Workholding is one of the most foundational concerns in machining. Regardless of whether you are turning, milling, or grinding, how you secure the workpiece determines repeatability, precision, speed, and final quality. Two of the most widely used devices in turning and general conventional machining workholding are the 3 jaw chuck and the Collet Chuck. Both tools have served generations of machinists and engineers, yet they possess distinct characteristics that make them suitable for different scenarios.

This comprehensive guide explores the practical differences between a 3 jaw chuck and a Collet Chuck, their advantages and limitations, and tips for choosing the right one for your application.

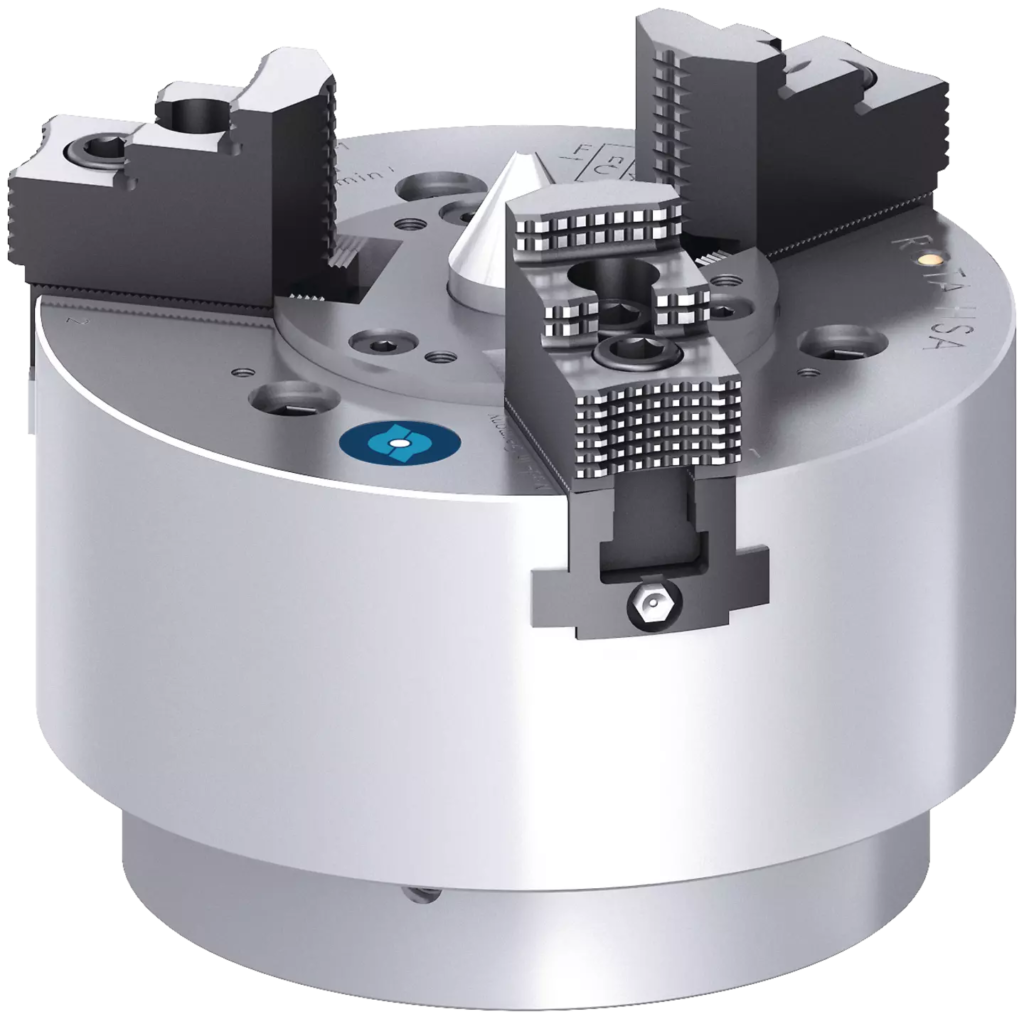

What Is a 3 Jaw Chuck?

A 3 jaw chuck is a workholding device commonly used on lathes and some milling or drilling machines. It features three jaws that move simultaneously when operated by a scroll mechanism or cam action. The synchronized movement centers the workpiece automatically, which makes setup fast and efficient.

The design of a 3 jaw chuck allows you to grip round, hex, and some irregular shapes with reasonable accuracy. It is typically considered a robust and versatile workholding method.

What Is a Collet Chuck?

A Collet Chuck, on the other hand, uses a collet—a cylindrical sleeve with a split body that contracts when tightened. The contraction grips the workpiece or tool with high precision. Collets are usually made to exact internal diameters and provide a uniform clamping force around the workpiece or tool shank.

Collet Chucks are widely used in high-precision applications, such as CNC turning spindles, milling tool holders, and grinding machines.

Key Differences Between 3 Jaw and Collet Chuck

Although both devices serve the purpose of holding a workpiece securely, there are several fundamental differences between a 3 jaw chuck and a Collet Chuck:

1. Clamping Mechanism and Accuracy

A 3 jaw chuck uses a scroll gear to move all jaws together, which provides good concentricity but is inherently limited by mechanical tolerances. Typical runout accuracy for a quality 3 jaw chuck may range from 0.08 to 0.15 mm, which is acceptable for general machining.

A Collet Chuck grips the workpiece uniformly around its surface, resulting in much tighter concentricity. High-precision collets can achieve runout values as low as 0.005 mm or better, which is crucial for precision machining.

2. Range of Workpiece Sizes

A 3 jaw chuck is designed with a broad gripping range, making it flexible for varying diameters and shapes. You won’t need to change jaws for every size within a reasonable range.

A Collet Chuck requires a matching collet for each specific diameter. While this ensures high precision, it can increase setup costs if you frequently change workpiece sizes.

3. Speed of Setup

A 3 jaw chuck offers quick setup because a single mechanism brings all jaws into position. For rapid job changeovers, this is ideal.

A Collet Chuck can take longer to set up because the collet must match the exact diameter of the workpiece. However, once installed, processes like tool changes and part swaps can still be rapid.

4. Holding Strength

Both devices can hold workpieces securely, but the nature of that holding differs. A 3 jaw chuck relies on mechanical leverage and jaw contact points, which provide excellent grip for heavier cuts and rugged machining conditions.

A Collet Chuck distributes clamping force evenly around the workpiece, which limits deformation and increases repeatability, but may not be as suitable under heavy radial or axial cutting forces without careful assessment.

Practical Applications for Each Device

Where a 3 Jaw Chuck Excels

- General Turning Operations: For rapid production or general lathe work where extreme precision is not mission-critical.

- Irregular Shapes: Jaws can grip hexagonal or irregular shapes more easily than collets.

- Quick Changeovers: Small runs with variable sizes benefit from fast clamping.

- Heavy Machining: Suited for roughing cuts and tougher materials.

Where Collet Chucks Excel

- High-Precision Machining: Where dimensional tolerance and surface finish matter.

- High RPM Applications: Balance and concentricity are more stable, reducing vibration.

- Small Diameter Work: Particularly in serial CNC production.

- Tool Holding in Milling: Collet Chucks are widely used for tool holding in milling centers and routers.

Interplay Between Precision and Productivity

One of the most common challenges machinists face is balancing precision with productivity. A 3 jaw chuck provides excellent productivity through fast setup and broad adaptability, while a Collet Chuck ensures the highest precision when it matters.

In many shop environments, you will find both systems working together:

- A 3 jaw chuck may be used for roughing operations where speed of setup and rough material removal are priorities.

- A Collet Chuck may be applied for finishing passes, precision drilling, or when surface quality and tolerance are critical.

Choosing the Right Workholding for Your Needs

Selecting between a 3 jaw chuck and a Collet Chuck depends on several factors:

1. Tolerance Requirements

If your part requires extremely tight tolerances, a Collet Chuck is often the better choice.

2. Part Geometry

Round and simple shapes work well in either device, but flats or non-standard shapes often require chucks with adjustable jaws.

3. Production Volume

High-volume production with identical parts often justifies investment in sets of collets for quick, repeatable workholding.

4. Machine Type

CNC machines with high rotational speeds pair particularly well with Collet Chucks due to improved balance and reduced runout.

5. Budget

Because collets need to be purchased in sets for each diameter, the initial investment may be higher than a versatile 3 jaw chuck.

Maintenance and Safety Considerations

Both devices require regular inspection to ensure reliable and safe performance:

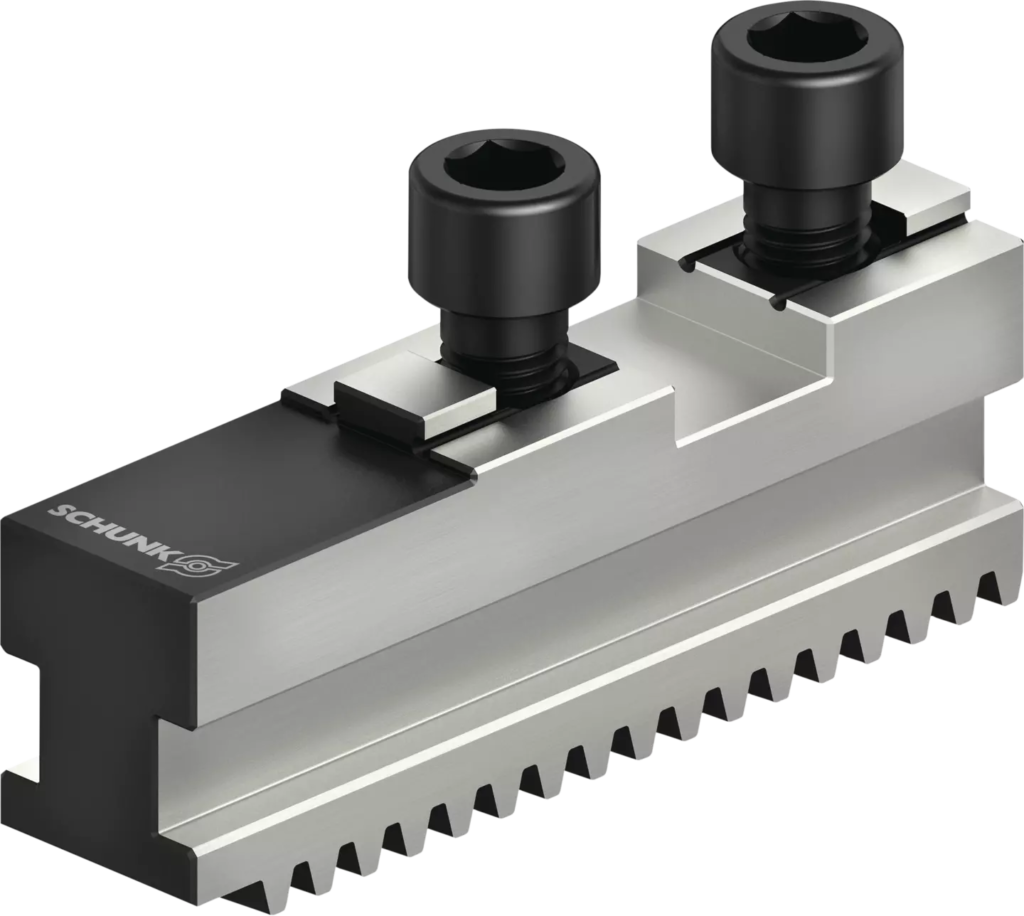

3 Jaw Chuck Care

- Clean jaws and scroll regularly to avoid debris build-up.

- Inspect for uneven wear and replace worn segments.

- Ensure mounting bolts are torqued correctly.

Collet Chuck Care

- Clean collets and internal surfaces after each use.

- Avoid over-tightening, as it can deform the collet.

- Store collets properly to prevent damage.

Proper workholding maintenance improves part accuracy and prevents costly tool or spindle damage.

Read also: Industrial Robot Gripper Solutions for Smart Manufacturing

Integration With CNC and Automation

Modern computer numerical control (CNC) systems often automate part handling, and workholding plays a key role in that integration.

For example:

- 3 Jaw Chucks may be used in robotic loading for varied jobs where part size changes are frequent.

- Collet Chucks are commonly used on multi-spindle machines and automated production lines due to consistent repeatability.

Automation benefits from the repeatability and balance of a Collet Chuck, while flexibility and versatility often favor the injection of a 3 jaw chuck.

Cost-Benefit Analysis: Real World Insights

While a Collet Chuck generally offers higher precision, the accompanying need for multiple collets can raise the total cost of ownership. In contrast, a 3 jaw chuck brings lower setup costs but may require more frequent adjustments to maintain accuracy.

In real shop scenarios:

- Shops with high mix and low volume may find a 3 jaw chuck more practical.

- High-volume, high-precision shops often justify the expense of multiple collets for consistent quality.

The right choice is often driven not by theoretical superiority but by practical shop workload and precision expectations.

Real World Case: Machining Precision Parts

In a production environment focused on small, precision parts, operators may choose a Collet Chuck to ensure consistency within micrometers. When parts are uniform and repetitive, the efficiency gained from the collet’s high accuracy outweighs the initial setup and tooling costs.

However, in a rapid prototyping environment where prototype parts vary in size and design, a 3 jaw chuck becomes invaluable for its adaptability and quick changeovers.

Understanding how each system aligns with shop priorities allows engineers and machinists to tailor their workholding strategy effectively.

Conclusion

The choice between a 3 jaw chuck and a Collet Chuck is not about which tool is inherently better, but which one best suits your machining needs. A 3 jaw chuck provides flexibility, speed, and ease of use, making it invaluable for general turning and varied part sizes. A Collet Chuck offers the precision and repeatability required for high-accuracy operations and high-volume CNC work.

Both workholding devices continue to play essential roles in modern machining practice, evolving with new materials, tighter tolerance demands, and automated environments. Combining the strengths of both can deliver optimal performance across a wide range of engineering and manufacturing applications.

In the hands of skilled operators and supported by quality tooling solutions from industry leaders like Schunk, machinists and engineers can achieve unmatched precision, productivity, and reliability in their operations.